1.

With Canada’s Cannabis Act, Bill C-45, passing its second senate reading, recreational legalization is middling toward reality across the country. As the provinces scramble to prepare for the unknown date, New Brunswick is notably on the ball when it comes to cannabis industry development. The province’s 2016 Economic Growth Plan naming cannabis as a priority sector, and business development experts at Opportunities New Brunswick predict a growth of 3,000 cannabis-related jobs by 2022. The drive to be a national leader in the cannabis industry is “vital” according to ONB senior director Steve Milbury, who is quoted on the company’s blog stating New Brunswick “will see real, positive economic results from being first out of the gate.”In 2017, research chairs at both the University of New Brunswick and Fredericton’s St. Thomas University announced programs focusing on scientific and clinical aspects of cannabis and its social and public health impact. (Pharmaceutical company Tetra Bio-Pharma is financing UNB’s program, while STU is sponsored by Shoppers Drug Mart.) The province was chosen as Most Progressive Public Office at the 2017 Canadian Cannabis Awards, and is the first to fully lock down its licensed medical producers as suppliers of recreational weed with federal legalization: Ontario conglomerate Canopy Growth Corp, Fredericton-based Zenabis (a brand of International Herbs Medical Marijuana Ltd.) and the Maritimes’ OG licensed producer, Organigram.

Organigram obtained its federal license to produce medical cannabis in April 2014—the 13th Canadian producer to do so. According to chief commercial officer Ray Gracewood, an import from Moosehead Brewery, OGI’s four years of operation in the medical market would equal four decades of experience in the alcohol industry. The company wasn’t even nominated in the 2016 Canadian Cannabis Awards, but in 2017 took home impressive titles including gold for LP Compassionate Pricing and the coveted Top Sativa title for its Wabanaki strain.

Organigram is currently seeing through a $60-million expansion of its homebase in an unassuming Moncton business park, doubling grow space to 23 rooms—roughly the size of a city block—and prepping to supply 5 million grams of recreational weed to the NB government. (Another million will cross the Confederation bridge for PEI consumers.) The revamps will grow production capacity from about 5,200 kilograms of medicinal cannabis per year to over 36,000 kilos a year by Canada Day, with the aim to evolve from a labour-intensive process to one that is fully automated. New extract labs, infused-oil labs and additional packaging areas will be built as well.

The renovation designs are all improvements on current cultivation and processing systems, which are highly monitored by the company’s Organigrow software. Multiple details of every single clone are monitored around the clock, making it possible to track specific elements in the growing process that incite changes in the plant. “Everything is calculated, and we know what to expect from our products,” says Gracewood. “Positioning ourselves as a data-driven facility is one of the best moves we've made.”

2.

Our facility tour begins in a staging area full of tiny baby clones. The nursery smells exactly like Halifax Seed or any Superstore gardening centre. A greatest ’80s hits playlist booms from PC computer speakers, and there’s a production line of mostly women wearing scrubs and hairnets, “correcting” the clones with scissors. Mike Koberinski, one of the facility’s production leads and the third grower to join the company, is our guide. He explains how the trimming process is used to foster better flower, noting that their candelabra structure creates room for giant colas to bloom—some nugs are known to grow the size of his forearm.Once corrected, the stock plants are stacked on five-foot carts under humidity domes; each cart containing around 1,800 plants. For two weeks they bask in 18 hours of simulated sunlight by way of metal halide high-intensity blue lighting, the colour cannabis prefers in this pre-vegetative phase. From here, the “pre-veg” plants are repotted and taken to the flowering room for another two-week phase of vegetative growth. Sunlight hours are reduced from an indigo 18 to a red-orange 12-hour-day, cueing the cannabis flower to blossom.

We meet an enthusiastic gardener named Alex, in the hallway between grow rooms, who explains how the natural world inspires Organigram’s simulated indoor garden: “Because cannabis is an annual plant it wants to grow, flower and produce seed in one season before dying off. Reducing daylight triggers the plant to flower, similar to how the sun effects outdoor plants. As the fall progresses, the spectrum of sunlight changes to give a more red spectrum because the sun is shifting angles in the sky. That’s when the flowering usually gets triggered outdoors, to reproduce before it dies.”

Organigram interrupts the reproductive process wild weed would undertake by keeping the plants in complete and utter darkness for their 12 hours of nighttime. Light leaks are “an undesirable trait” that add undue stress on the plant, just as one gets the grumps if woken up in the middle of the night. Light leaks are known to produce male flower parts on female clones as well, so the absolute darkness actually keeps OGI’s female-only clones from seeding themselves. “Sensimilla—plant without any seed—makes for a higher quality product,” says Alex. Sticking with sensimilla ensures customers aren’t spending cash on weighty non-consumable plant product.

The vegetative phase leads to the 52-day flowering phase. This takes place in Organigram’s signature three-tier growing system, where each grow room can yield between 100 and 200 kilograms of dried flower per harvest. Weed’s wonderful smell is thick here, the tall plants glistening with hair and kief. A split room of CBD Shark and golden girl Wabanaki shows the physical contrast between different strains—sleepy squat indica leaves drooping over one another, beside more spherical, coiled, active plants. The Organigram grow rooms take two days to harvest, and then are stripped, sanitized and reset for the next crop to move in.

3.

Today Organigram is focused on segmentation, what Gracewood calls “truly understanding how to get four amazing products from one specific plant.” OGI recently introducing a line of mini buds, which come from the lower part of the plants and therefore share genetics, but are more conservative in their size, cannabinoids and price point ($8/gram). In the name of maximizing plant potential and ensuring each unique patient has their needs met, blended pre-milled products are sold for extremely competitive low prices ($5-7/g).After years of researching Organigrow data, OGI has launched The Edison Project, top flower strains that boast the company’s most luscious medicine. These gigantic flowers are hand-manicured and craft-cured at optimal temperatures, maximizing chlorophyll breakdown in the name of producing a “distinct, alluring flavour and aroma.”

A room full of long, vibrant Indica Hash plants, the street name for Organigram’s Edison #3, is redolent of sweet grape and slight pepper. These shimmering and stunning flowers still have two more weeks to “fatten up” before harvest, and develop even more crystal resin. The line tops OGI’s price point at $15 per gram, and I dream of affording it.

“What we know and can translate from the medical side to adult rec is that the best marketing strategy is good product,” says Gracewood. “What we can do as an indoor, world-class grower is create a product unlike anything else in the industry. There will always be room in the market for the highest quality product. We've made the right decisions good place today, and for tomorrow.”

4.

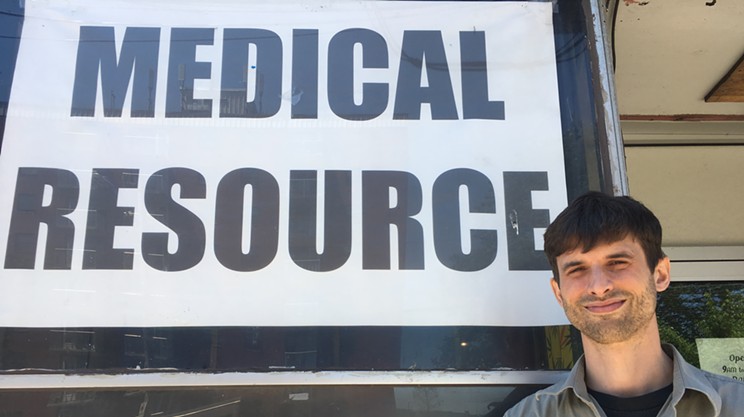

My first Organigram toke was on the sativa strain Acadia, marketed on OGI’s website as combatting depression, pain and lethargy, with 22 percent total THC. I ordered online with my medical prescription, and HST and $10 for Canada Post delivery to the cost of my medicine.The spliff I rolled after it arrived was the cleanest, smoothest smoke I’ve ever hauled.

I sat cross-legged on the washing machine, drinking in the silky clouds and exhaling the tart taste of summer berries. I was shocked to see I’d washed the whole thing down in just two minutes, “almost a little too sweet” Maria Bamford might say. My mind was buzzing, and I was certainly more “stoned” than my elevated tolerance has allowed in ages. However, I felt completely relaxed and capable, not a spark of paranoia despite a higher dosage than usual.

I rambled about the mind-blowing “quality” of the bud to my partner, who told me I was a “liker” and said touring the facility made me toke the Kool-Aid. Those might have been words spoken in jealousy, by a person without a prescription and thus facing a wait until rec legalization comes through to buy some Torbay indica of his own. But there’s something to be said for appreciating a product more after you know how it’s made.

At Organigram I saw every stage in the process from young plants to the shipping room, and behind it all the systems to make cannabis growing standardized, secure and repeatable. Plant clones, testing labs, the hairnet I wore during the tour, purpose-built rooms, lighting schedules, an ID badge check at every door, surveillance cameras everywhere, terpene profiles listed online with each strain’s THC and CBD percentages.

I’m two months deep into my OGI prescription now, and to my surprise have fallen most passionately for the Baleen strain. It’s an oceanic and earthy take on CBD Shark, giving a very gentle high with an 11 percent CBD to 6 percent THC ratio, and I absolutely devour it come the 10 awful days of menstrual cycle. CBD is extremely soothing and has better anti-inflammatory properties than a turmeric almond latte. The Baleen phenotype tests high in terpenes called pinene and limonene, compounds also found in pine needles and citrus peels known to uplift both mood and mental clarity.

Most of the weed I’ve smoked in my life, I had no idea where it came from. Now I have access to the sort of information that comes from legalization and legitimacy. Being able to trust today’s Baleen will be the same at every Rx refill is comforting to the rampant anxiety that smoking weed helps combat in the first place.

5.

“The biggest difference from my experience working with beer, is that I worked within a very mature market comparatively,” says Gracewood. He oversees all commercial aspects of the Organigram business including branding, marketing, sales strategy, customer service, partnerships and strategic alignments—the same branches he lead at Moosehead Brewery for nearly 12 years. “The alcohol industry has years and years of experience and data to understand trends and consumer habits. With cannabis, there is plenty of information available through the illicit market, but it’s nothing in comparison to the beverage and alcohol industry.”There is clearly a lot to learn about the growing business from medicinal legalization. Using information from the medicinal world and lessons learned on the illicit markets, Gracewood says the cannabis industry must work actively to “put through a regulation filter for public safety and strategize keeping cannabis out of the hands of Canada's youth. There can never be too much conversation around education about the product, responsible use and dosages, and how and why we keep it away from children.” To Gracewood, the more cannabis features in public consciousness, the safer the legalized frontier will be moving forward. “A responsible industry is a successful industry.”

The success of Organigram hints at the growth that could create New Brunwick’s projected 3,000 jobs. Alongside UNB and STU’s programs, le Collège Communautaire du Nouveau-Brunswick collaborated with Organigram and the New Brunswick Department of Post-Secondary Education on a pioneer training program for cannabis cultivation technicians. The entry level, “industry designed” course blends horticultural and cannabis-based training over a 12-week period, which include visits to Organigram’s facility for hands-on training. Tuition is completely covered by the New Brunswick government.

6.

Like most producers, crown employees, police forces and jurisdictions, Organigram still faces challenges in terms of adult rec readiness. One example is the package design for weed that will sold in retail shops. “We’re trying to navigate through the packaging and labelling process, when we don’t even know what information will be required on labels,” Gracewood explains. If Organigram is going to be ready by July, August or even September, he wants the packaging prototypes done yesterday.“Design-wise, Organigram and any business signed-on to provide cannabis for the LCs are trying to cram a two-to-three-year process into a matter of months. We’re making a lot of decisions without knowing all we need to in terms of product description requirements, SKU sizes, the list goes on. Our team is doing the best we can under a very tight timeline.

“But we don’t need to solve all the issues overnight. Legalization will be a process and take place over time. I’m already inspired by how the conversation has changed in the past two years I’ve worked in the industry.”

Although legalization won’t change attitudes overnight, Gracewood believes Canadians are starting to openly embrace cannabis not just from a medical standpoint, but for its “social aspects” as well. To him, “intense focus on training and education” for front-line workers, physicians, consumers and the general public is key in overcoming many dank decades of stigma. And in this evolving future—with Organigram’s cutting-edge technology coming out of Moncton, industry dedication from a supportive government and innovative secondary education programming—New Brunswick’s high hopes to lead the post-prohibition cannabis sector are off to a blazing start.

Lucy LaPlante reviews pot for The Coast and is an expert advisor on cannabis consumption. Email your questions to her at [email protected].